As an important member of the cellulose ether family, hydroxyethyl cellulose (HEC) HE300, with its unique properties, has demonstrated outstanding application value in fields such as building materials, chemical synthesis, and energy extraction. This article will delve into the core advantages of HE300 in self-leveling mortars, emulsion polymerization, and oil drilling, providing key material support for industry innovation.

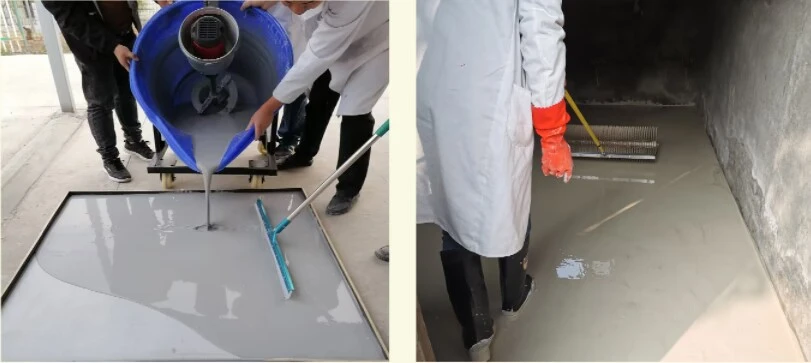

I. Self-leveling Mortar: The "Golden Duo" of High Water Retention and Flowability

In the application of self-leveling mortar, HE300 stands out as a key ingredient due to its excellent water retention and thickening properties. Its advantages include:

- Precise Water Control: Slows down water evaporation, ensuring complete hydration of cement and preventing cracking and hollowing.

- Dynamic Flowability: Optimizes the fluidity of the mortar, enabling self-leveling on low slopes and enhancing construction efficiency.

- Enhanced Adhesion: Improves adhesion to the substrate, reducing the risk of delamination.

II. Emulsion Polymerization: The "Invisible Guardian" Stabilizing the Reaction

In the polymerization reactions of acrylate, styrene-acrylic emulsions, etc., HE300 plays an irreplaceable role as a protective colloid:

- Phase Stability: Effectively disperses monomer particles, preventing flocculation or agglomeration during the polymerization process;

- Viscosity Control: Precisely regulates the viscosity of the reaction system, adapting to the requirements of different polymerization processes;

- Environmental Compatibility: Non-ionic nature, compatible with various additives, reducing side reactions.

III. Petroleum Drilling: The "Lubrication Expert" for Efficient Drilling

HE300 stands out in oilfield drilling fluids: - Salt and Temperature Resistance: Maintains stable viscosity in high-temperature and high-salt formations, ensuring drilling safety.

- Loss Reduction Performance: Forms a dense filter cake, reducing the infiltration of drilling fluid water into rock layers.

- Environmentally Friendly: Biodegradable, minimizing the risk of pollution to underground environments.

Industry Outlook

With technological advancements and increasing environmental protection requirements, the modified versions of HE300 and its composite application solutions will continue to drive performance upgrades across various fields. "The multi-functionality of HE300 makes it a 'bridge material' across industries, and it holds great potential in emerging fields such as new energy and 3D printing in the future."

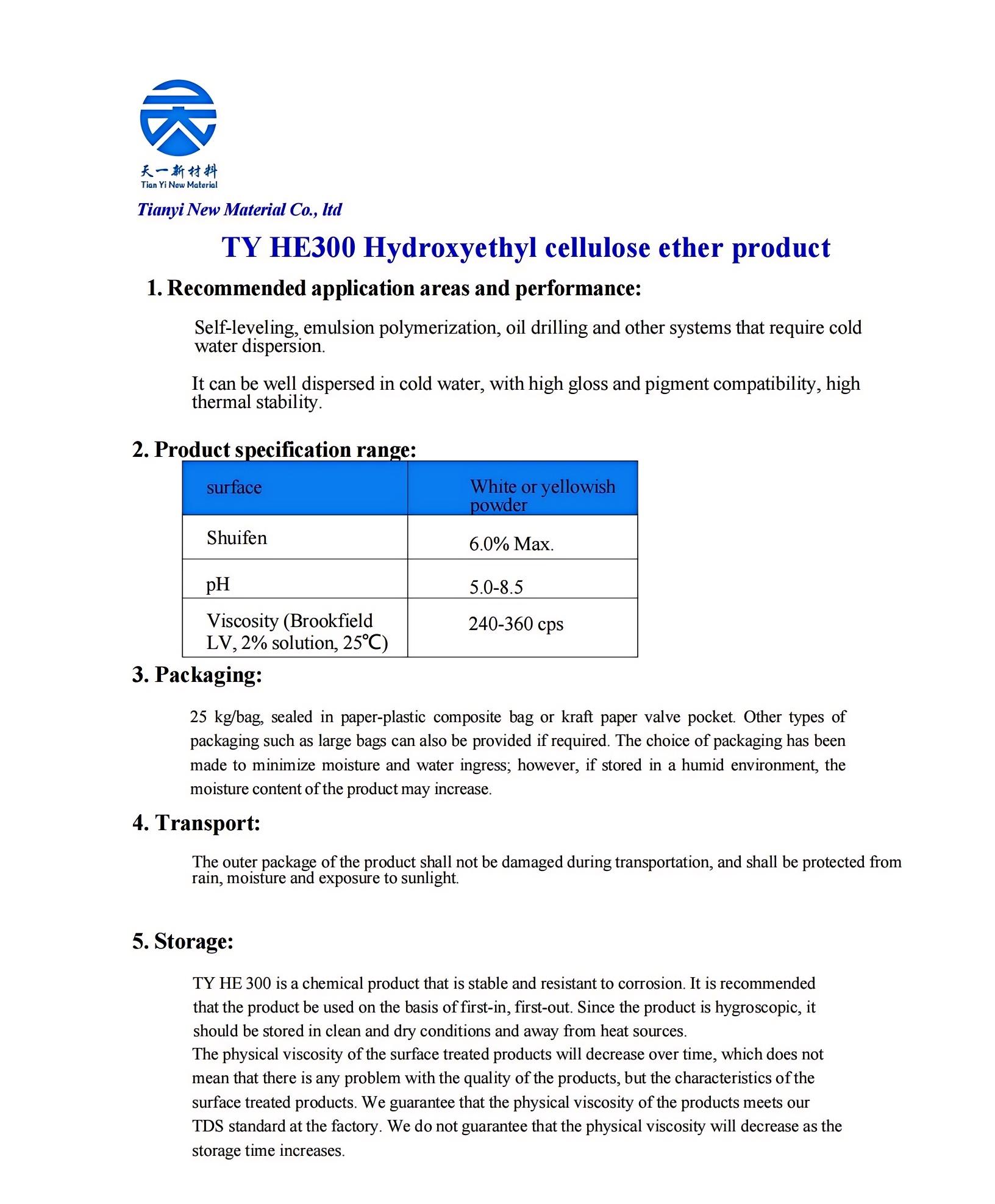

About HE300

Hydroxyethyl cellulose HE300 is a water-soluble nonionic polymer, made by alkali treatment of refined cotton fibers followed by etherification with ethylene oxide. It features rapid dissolution and high purity, and is widely used in industrial and specialty chemical fields.